In today’s fast-paced industrial landscape, where productivity and efficiency reign supreme, the demand for sophisticated packaging solutions has never been greater. The automatic piston liquid filling machine is one such indispensable asset that has revolutionized liquid packaging. Combining precision, speed, and reliability, this advanced device has found widespread use in various industries.

Components and Working Principles

Main Components of an Automatic Piston Liquid Filling Machine

At the heart of the Automatic Piston Liquid Filling Machine lies a complex arrangement of components, each serving a crucial role in achieving flawless liquid filling. The primary elements include the following parts.

Hopper: The hopper acts as a reservoir for the liquid, ensuring a continuous supply during the filling process.

Conveyor System: This facilitates the smooth transport of containers to be filled, maintaining a seamless workflow.

Filling Nozzle: The filling nozzle is the gateway through which the liquid is dispensed into the containers, which is designed to prevent spills and maintain accuracy.

Piston Assembly: The piston mechanism is the core of the machine. It controls the precise volume of liquid to be filled into each container, promoting consistency and reducing wastage.

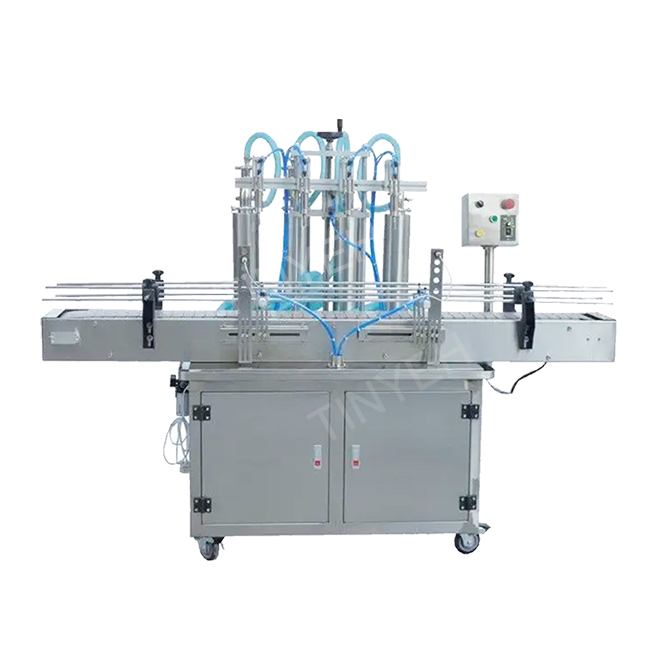

automatic piston liquid filling machine

How the Machine Works

The automatic piston liquid filling machine operates on a well-engineered working principle, bringing harmony to its various components. The filling process can be summarized in three main stages:

Filling Process: When the containers are in position, the liquid is drawn from the hopper into the piston assembly. The piston moves down, creating a vacuum that draws the liquid into the cylinder.

Piston Mechanism: As the piston moves back up, the liquid is forced out through the filling nozzle, accurately measuring the predetermined volume. The speed and precision of this mechanism contribute significantly to the machine’s reliability.

Control Systems: The entire process is meticulously monitored and controlled by advanced systems, ensuring consistent fill levels and seamless integration with other packaging components.

Major Sectors of Automatic Piston Liquid Filling Machine

The versatility of the automatic piston liquid filling machine goes beyond its applicability in multiple industries. It also accommodates a wide range of liquid viscosities and container sizes, making it an ideal solution for various product lines and redefining their packaging capabilities.

Pharmaceutical Industry

In pharmaceuticals, where precise dosing is paramount, the machine guarantees accurate fill volumes, enhancing product quality and safety. The automatic piston liquid filling machine adapts to varying liquid consistencies, from viscous syrups to delicate injectables, meeting the industry’s diverse needs.

Food and Beverage Industry

Different liquid densities, from watery beverages to thick sauces, are handled efficiently, offering convenience to food manufacturers. Whether filling bottles with sauces, beverages, or condiments, the automatic piston liquid filling machine ensures hygienic and consistent packaging.

liquid packaging machine manufacturers

Personal Care and Cosmetics Industry

Fragrances, lotions, and cosmetic products demand precise fillings to maintain brand integrity, a task the automatic piston liquid filling machine fulfills with ease. It caters to a plethora of cosmetic products, ranging from light lotions to denser creams, providing flexibility in packaging options.

Chemical and Petrochemical Industry

Dealing with hazardous chemicals requires precision and control, attributes effortlessly offered by the automatic filling machine. That means harsh chemicals with different viscosities find their appropriate containers with ease, preventing cross-contamination and ensuring safety.

Conclusion

The automatic piston liquid filling machine is a testament to human ingenuity and technological advancement in the realm of liquid packaging. Its precise filling capabilities, versatility, and adaptability across industries have elevated liquid packaging standards, benefiting consumers and manufacturers alike.

If you are looking for reliable automatic piston liquid filling machines, Tinyeh can give you a hand! As one of the leading liquid packaging machine manufacturers in China, we have the ability to offer more efficient and sustainable packaging solutions for your project!