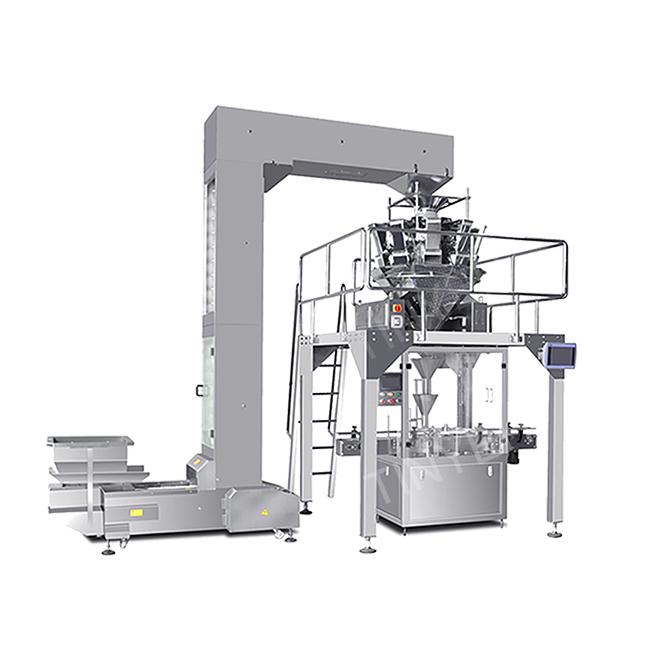

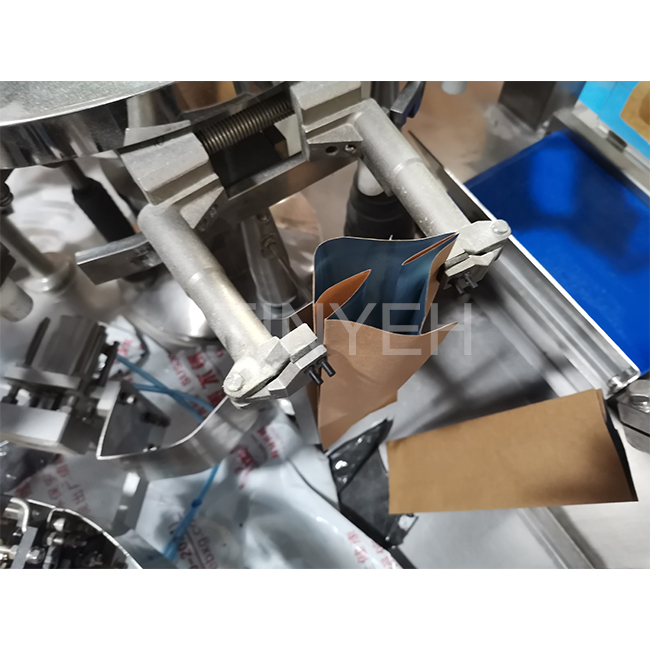

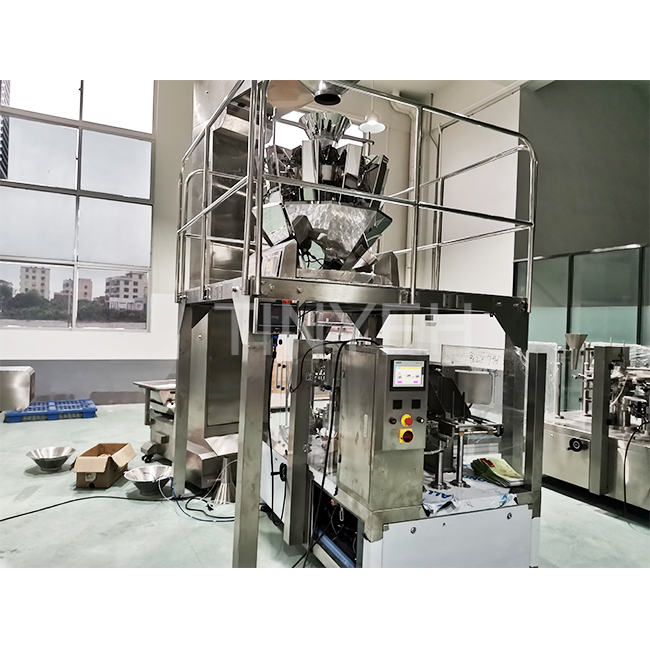

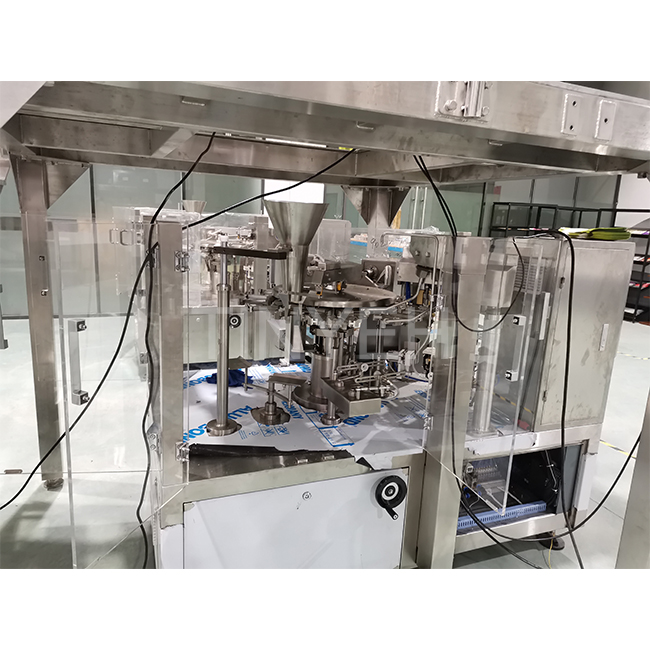

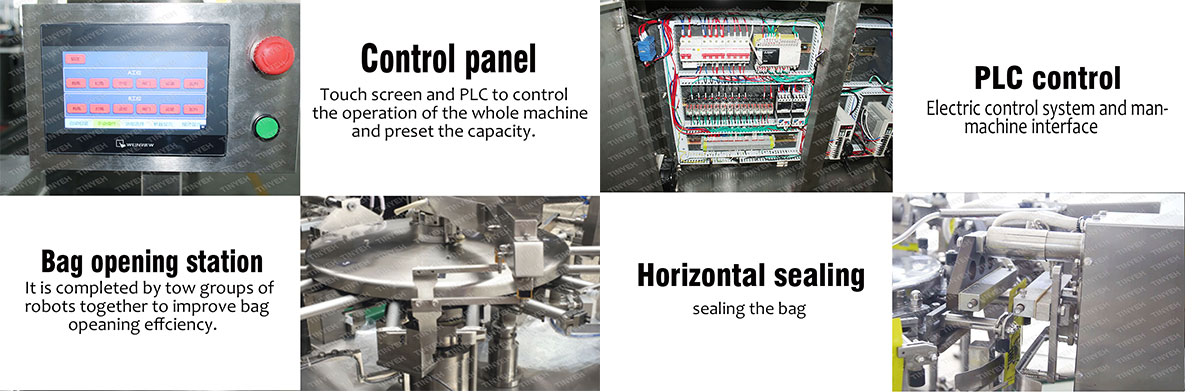

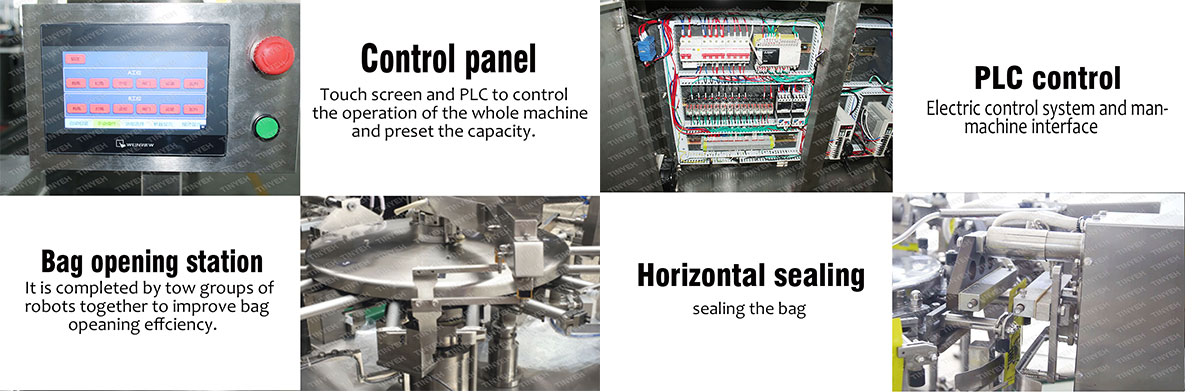

Automatic rotary packing machine adopt precision indexing device and PLC to control each action and working station to make sure the machine operates easily and does accurately.

The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch.

Automatic checking system can check bag situation, filling and sealing situation.

The system shows: 1.no bag feeding, no filling and no sealing; 2.no bag opening/opening error, no filling and no sealing; 3.no filling, no sealing.

The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

Q: How can I find a reliable nuts packing machine factory?

A: When searching for a reputable nuts packing machine factory, consider factors such as their experience, customer reviews, certifications, and the range of products and services they offer. Request samples and inquire about their manufacturing process to ensure their quality standards align with your requirements.

Q: What materials are commonly used by dry fruit packing pouch manufacturers?

A: Dry fruit packing pouch manufacturers often use materials like laminated films, aluminum foil, high-density polyethylene (HDPE), or polyethylene terephthalate (PET). These materials provide excellent barrier properties, ensuring your dry fruits stay fresh.

Q: Can dry fruit packing pouches be customized with my brand logo?

A: Yes, most dry fruit packing pouch manufacturers offer customization options, including the ability to print your brand logo, tagline, or artwork on the pouches. This helps to create unique and recognizable packaging that represents your brand identity.

Q: What is the typical lead time for manufacturing dry fruit packing pouches?

A: The lead time can vary depending on the manufacturer's production capacity, the complexity of your packaging design, and the number of pouches required. It's best to discuss this with the manufacturer directly to get an accurate estimate.

Q: Can dry fruit packing pouches be used for other products besides dry fruits?

A: Absolutely! While dry fruit packing pouches are specifically designed for dry fruit packaging, they can also be used for various other products like nuts, seeds, granola, and even non-food items like powders, supplements, and small accessories.

Q: Are there any regulations or certifications I should consider when choosing a nuts packing machine factory?

A: Yes, it's important to ensure that the manufacturer complies with food safety regulations and certifications. Look for manufacturers who adhere to standards such as ISO 9001 and have certifications like BRC (British Retail Consortium) or FDA (Food and Drug Administration) approvals, indicating their commitment to quality and safety.